Air Bags BASE AIR BAG™

Protect your products:

absolute safety for your shipments.

MANICARDI ® air bags, inflatable cushions used to secure and stabilise the load during transport, are strong, economical products available in several formats.

MANICARDI ® inflatable bags are placed in the empty spaces between packages while loading them, generally in containers or railway wagons.

Once inflated to a certain operating pressure, the air bags fill the originally empty space, creating an immobilising force that prevents the load from moving during transport.

Commonly used by companies that offer logistics and transport services or for export by sea or land, using them properly ensures the goods reach destination with no damage.

Correctly securing the load with MANICARDI ® air bags prevents accidents and improves overall safety and efficiency in the transport sector.

The Base Air Bag™ is the most economical solution for immobilising goods for loads with a total weight under 16500 kg.

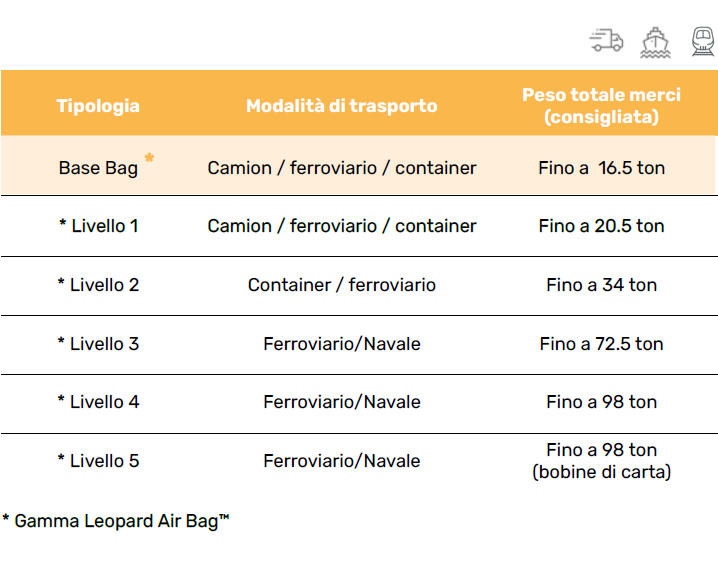

Originally developed for non-heavy duty use, today they can be used as a space filler inside wooden crates, for shipping furniture, machinery and components in general. They complete the range of A.A.R certified air bags in the Leopard Air BAG range:

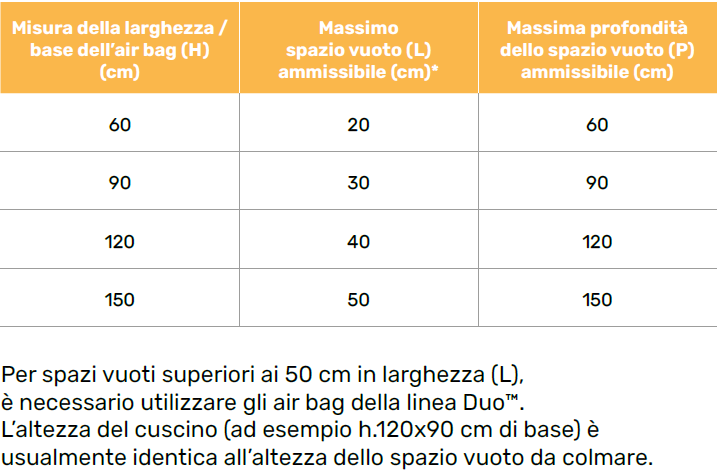

The right format to use for safeguarding loads is sized according to the weight and size of the goods to be immobilised and the width of the empty space left between the packages inside containers/railway wagons/trailers.

Formats available

The Base Bag line can be made with the standard width of 60/90/120/150 cm. For each width it is possible to make air bags with heights of 60/90/120/150/180 cm.

BASE AIR BAG™

Technical features

The inflatable cushions in the Base BAG line are made of recyclable plastic covered with a layer of polyethylene to obtain greater resistance to perforation. For fast and easy inflation, the cushions are fitted with a spring valve that ensures the correct operating pressure throughout transport.

- External material: Polypropylene

- Weight -65 g/m2 + 15 g/m2 (Lamination)

- Internal material: Extruded polyethylene

- Maximum working pressure: 2 PSI

- Burst strength: 5 PSI

- Spring check valve in front or side position